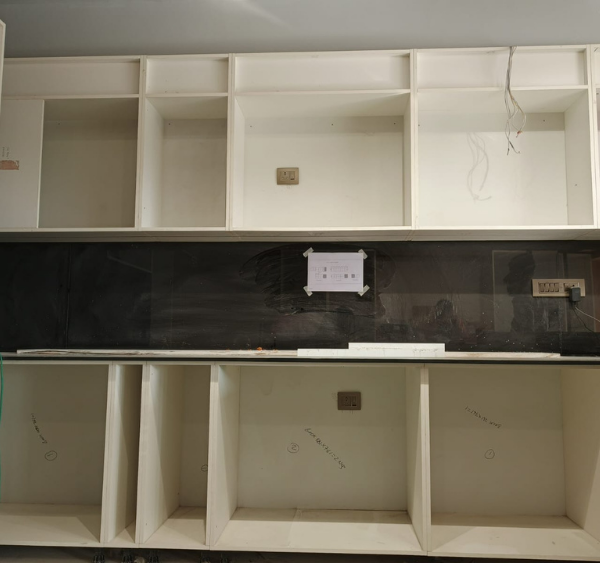

WPVC is an important product composite made with poly vinyl chloride. PVC is the material

which has good and positive tendency towards surface enhancement. Thus, WPVC boards and

WPVC profile can be painted, colored, coated, varnished and laminated with different

surface materials. There are different adhesives available for WPVC surface from different

companies including pidilite Industries. High pressure laminates, Veneers and other

decorative surface can be laminated by Fevicol SR Heatex , royal bond 9 type of adhesives.

These adhesives can be used for manual pressing and cold pressing applications of boards

and surface. For joining applications PVC solvent cements are also available and which can

be used for rapid joining.